Currently I live in a house, built in 1964, this sometimes means that I have to deal with problems being that the construction is on the older side. Back then people put their washing machines in the shed or in the kitchen, nowadays I prefer it in the attic as it doesn’t intrude the living space this way.

Having it in the attic means dealing with vibrations, as the floors are made from wood while modern structures mostly use concrete.

I have tried a lot of different solutions, anti vibration pads made from rubber, adding mass by putting the washing machine on concrete tiles, but it kept dancing around happily.

After a lot of reading and buying a brand new Miele, I decided it was time for something different, I’ve read that the best way is to strengthen the structure beneath it.

The three beams are made up from two 5x5x140cm beams, glued together and then screwed into the floor beams, I was able to track them down by making a small cut with a multitool and then sticking a blade through and see where it is held back by the beams below.

I chose to keep the underlayment between the new beams as it was easier for me. To screw the beams into the floor I used M10x200mm wood screws and M10x2,5 sheet metal rings, pre dill the holes in the beams below with a 6mm drill.

I added rockwool in the empty room to avoid creating a sound chamber and to top it off I used 1,8x60x120cm Multiplex, which I treated with some wood finish.

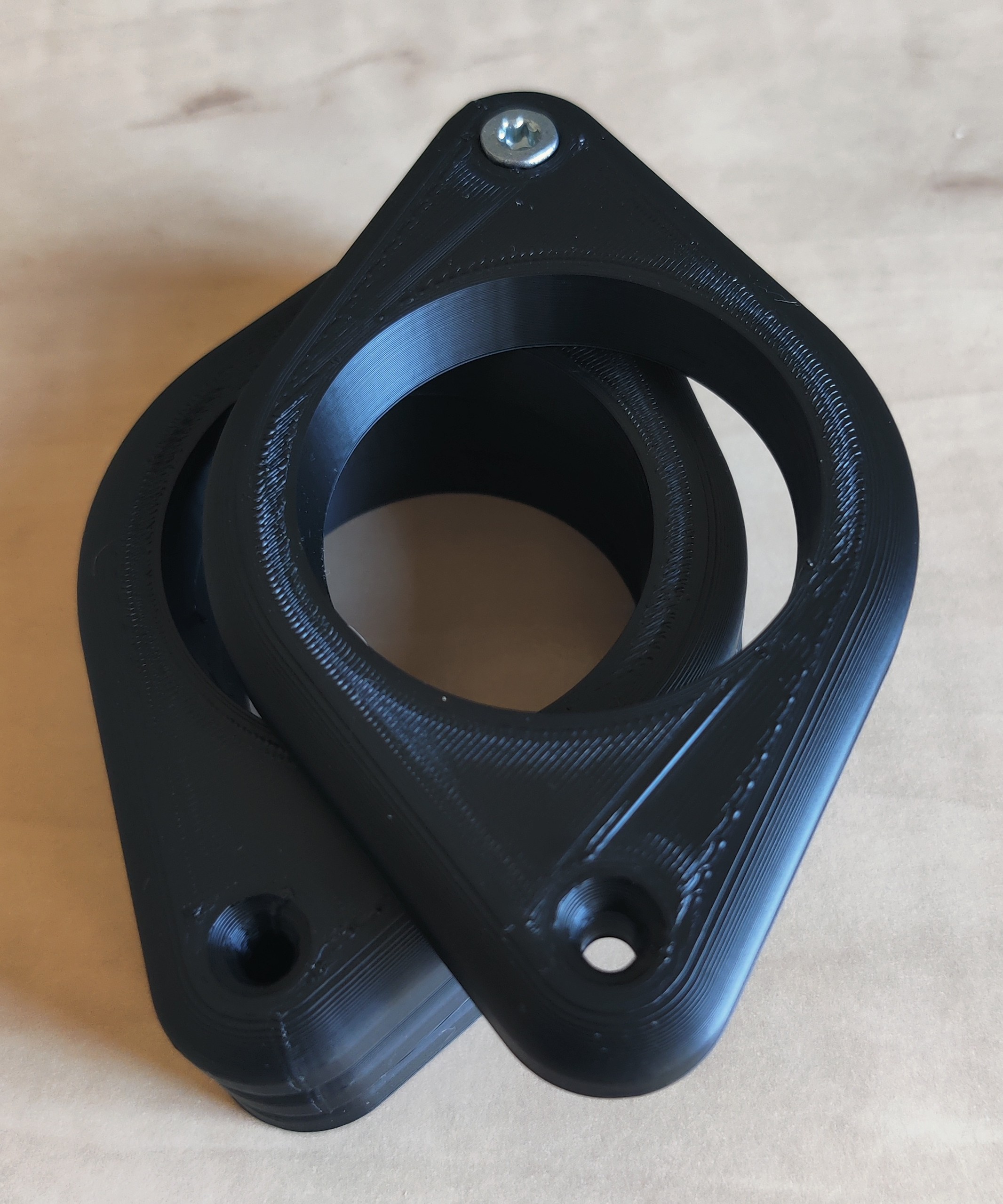

The washing machine now stays rock solid, it does still vibrate a bit but much less and without dancing, however to be safe I designed and 3D printed some feetlocks which I screwed to the top, this way it shouldn’t be able to fall off as the feet are now constrained with a bit of play.

As pictures say more than a thousand words, I will showcase the project below in pictures.